- Please select your vehicle fitment -

Achieve the ultimate in stopping power with the CTE Carbon Ceramic Matrix (CCM) Brakes. By upgrading from regular Iron Brakes to Carbon Ceramic, you can experience a dramatic increase in braking performance throughout the temperature range.

Diamond Cut to exacting tolerances from T700-Grade Continuous (Long) Carbon Fibre

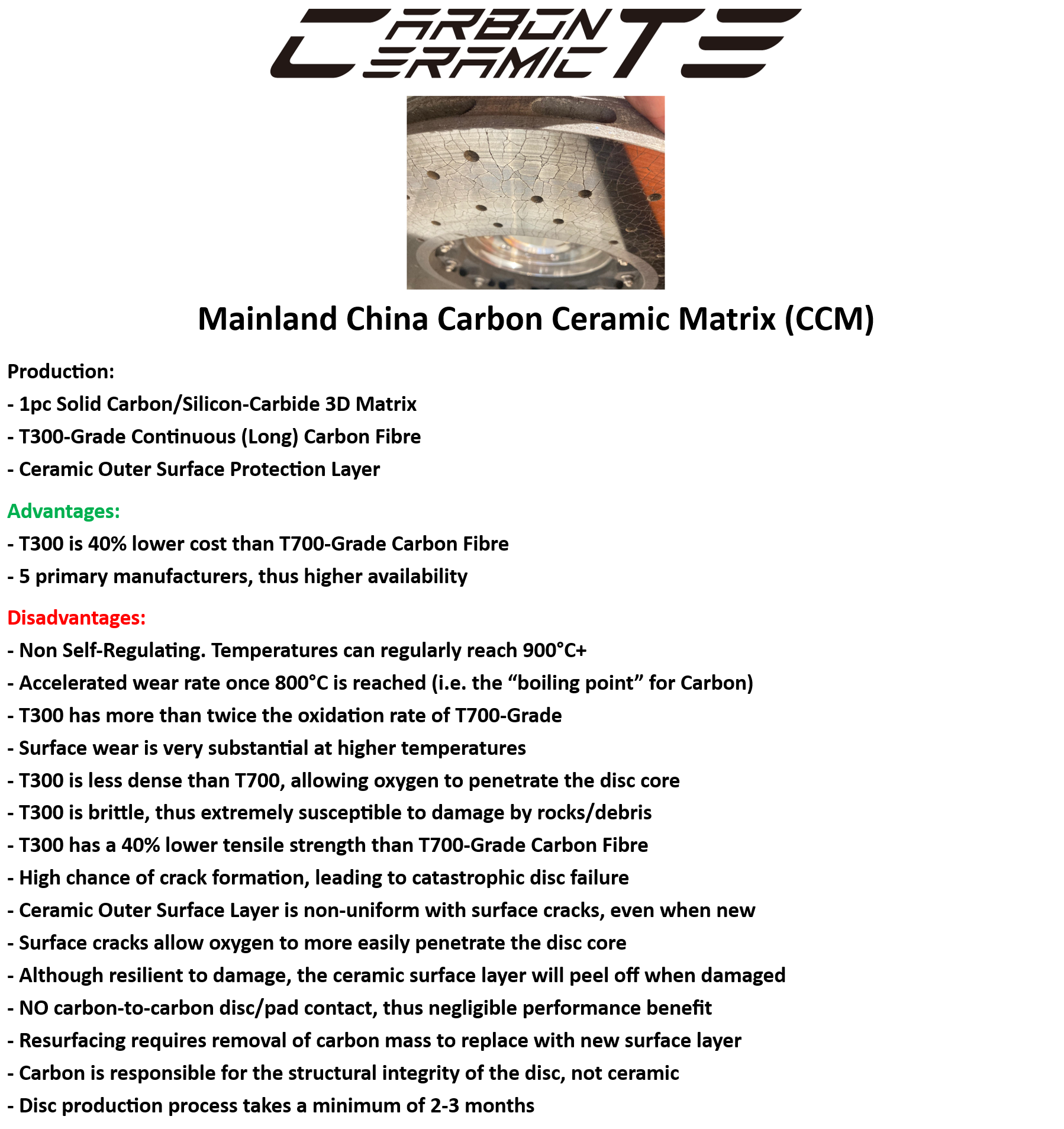

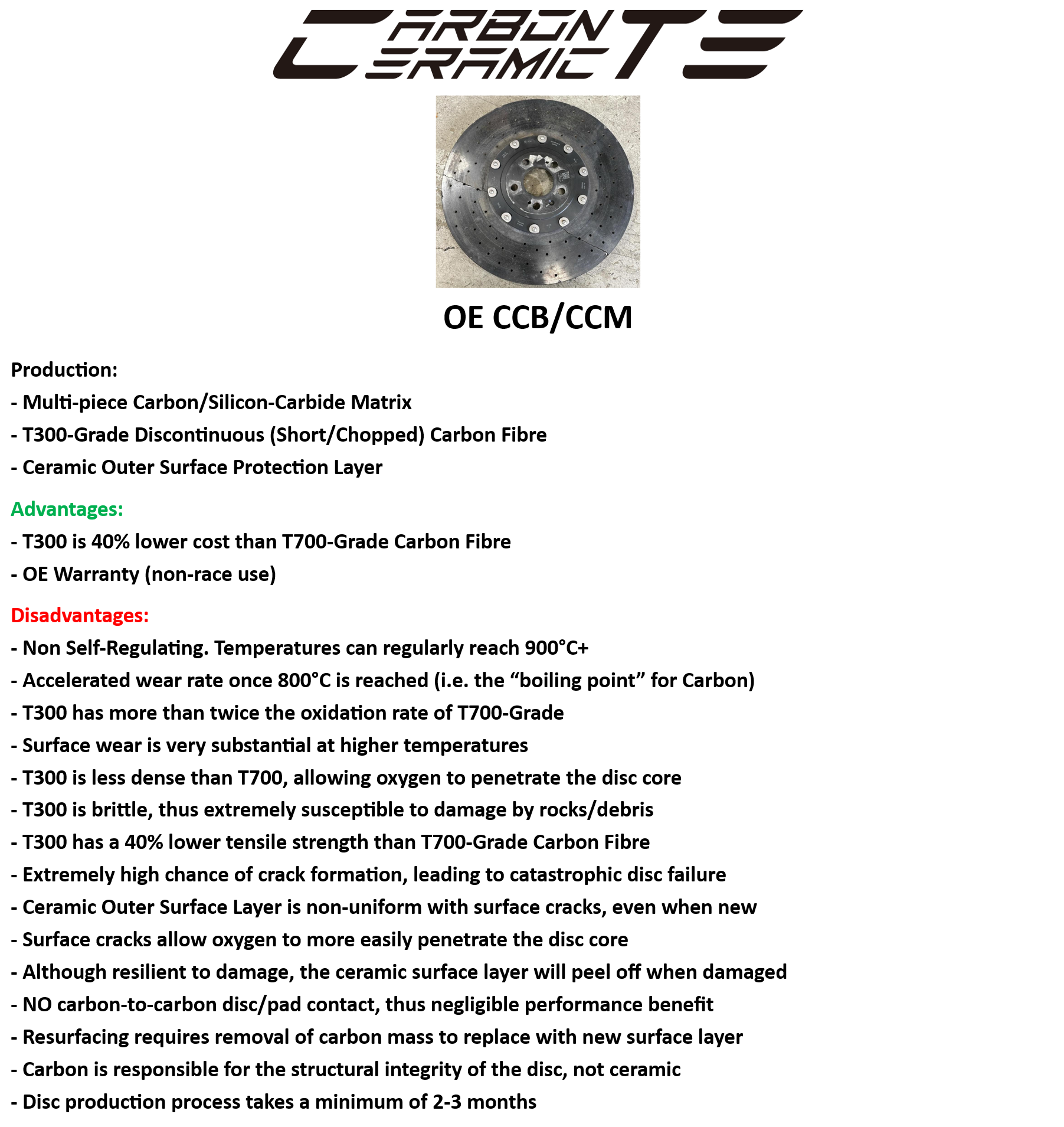

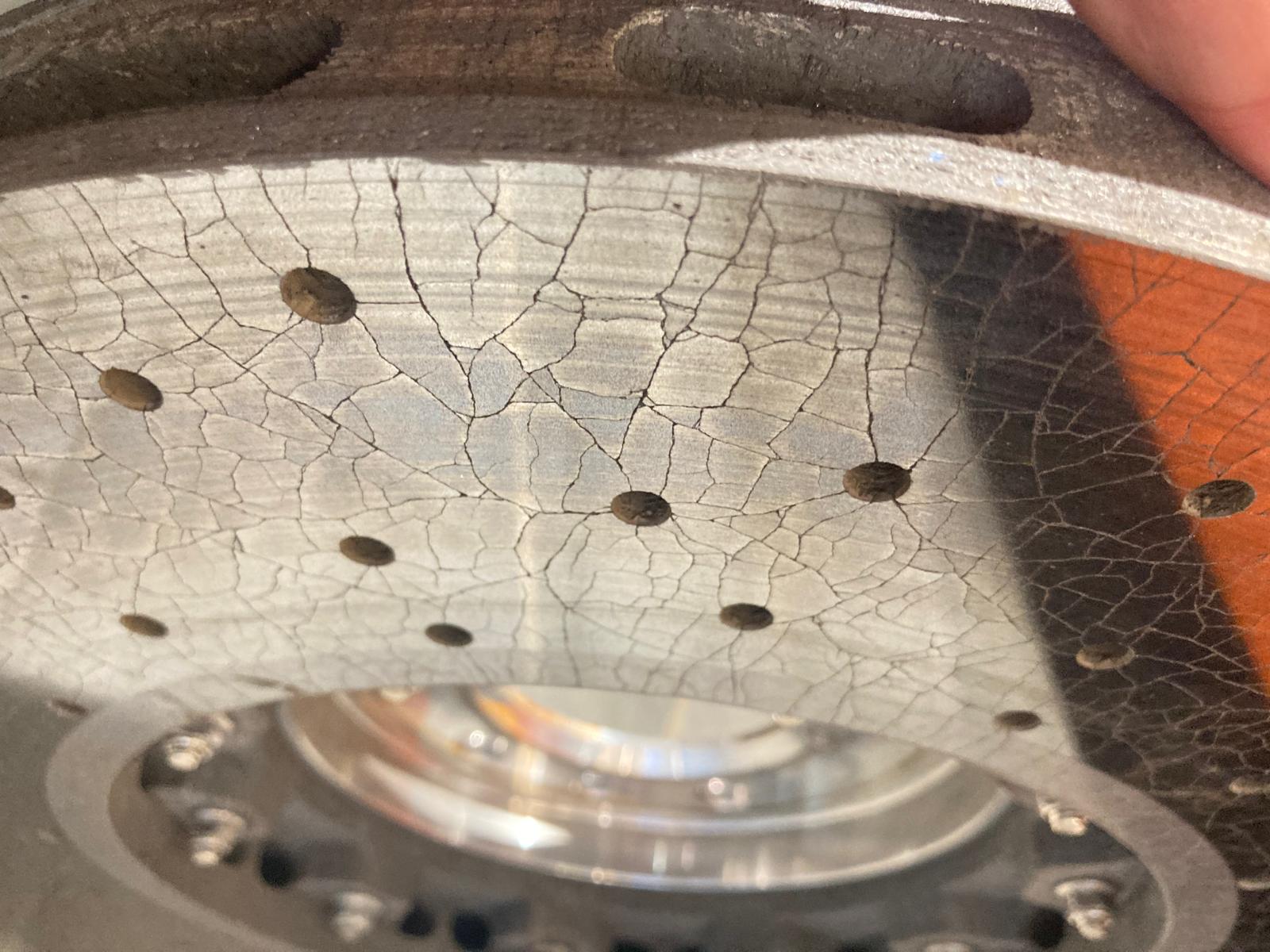

Our near-peer competitors use inferior T300-Grade Continuous (Long) Carbon Fibre (T700 has a tensile strength approximately 40% greater than the cheaper T300 grade), while most other competitors on the market (including Brembo/SGL and OE, which are no different from the cheap Chinese Knock-Offs available) cut corners and use T300-grade Chopped (Short) Carbon Fibre, which is the primary reason for the infamous cracked discs, giving CCM Brakes their bad reputation.

Designed using leading-edge Solidworks 3D CAD & Cosmos FEA software

Advanced heat profiling and rigorous real-world testing in partnership with both OE and professional race teams (Ferrari S.p.A's 488 Challenge Cars, BYD Auto's U9 Hypercar and Three Five Motorsport's Rally Cars, to name a few) around the world ensure a competitive advantage over our competitors! Fully inclusive testing covers our 3 main target markets: Professional Circuit Racing, Professional Rally Racing and High-End Street Performance.

Our Winning Formula?: 100% "Vertical Integration Manufacturing" + Governmental & Military Contracts + OE Contracts (Aerospace & Automotive). By fully controlling our supply chain, this allows us to offer "Superior" consumer-level products at significantly "Lower Cost" than our competitors!

Specifications

For Race Applications

Diamond Cut to exacting tolerances from T700-Grade Continuous (Long) Carbon Fibre

Our near-peer competitors use inferior T300-Grade Continuous (Long) Carbon Fibre (T700 has a tensile strength approximately 40% greater than the cheaper T300 grade), while most other competitors on the market (including Brembo/SGL and OE, which are no different from the cheap Chinese Knock-Offs available) cut corners and use T300-grade Chopped (Short) Carbon Fibre, which is the primary reason for the infamous cracked discs, giving CCM Brakes their bad reputation.

Designed using leading-edge Solidworks 3D CAD & Cosmos FEA software

Advanced heat profiling and rigorous real-world testing in partnership with both OE and professional race teams (Ferrari S.p.A's 488 Challenge Cars, BYD Auto's U9 Hypercar and Three Five Motorsport's Rally Cars, to name a few) around the world ensure a competitive advantage over our competitors! Fully inclusive testing covers our 3 main target markets: Professional Circuit Racing, Professional Rally Racing and High-End Street Performance.

Our Winning Formula?: 100% "Vertical Integration Manufacturing" + Governmental & Military Contracts + OE Contracts (Aerospace & Automotive). By fully controlling our supply chain, this allows us to offer "Superior" consumer-level products at significantly "Lower Cost" than our competitors!

Specifications

- Made from T700-Grade Continuous (Long) Carbon Fibre in a 1pc Solid 3D Matrix

- 2pc floating brake discs. Bells are machined from Forged 6066-T6 Aluminium (not the cheaper 6061-T6 as commonly used by our competitors)

- Patented fastener mechanism, consisting of larger M8 bolts (not the common M5 or M6 used by our competitors) forged from Stainless A4-70 grade steel

- Dynamic Test Simulations on our in-house Link & Horiba Brake Dynamometers ensure optimum performance under ALL conditions

- Non Surface-Coated Discs, offering genuine Carbon-to-Carbon disc/pad contact. Inferior discs with a Ceramic Outer Surface Layer offer negligible braking performance benefit over regular Iron discs

- ECE R90 E11 Certified Brake Pads. Choose between Street or Race Pads when ordering

- The ONLY brake manufacturer in the world actively pursuing TUV certification of Carbon Ceramic Brake Discs. Whilst it is mandatory for regular aftermarket Iron discs to be TUV certified, this does not currently apply to aftermarket Carbon Ceramic Brake Discs

- CTE Carbon Ceramic Brake Discs can be resurfaced approx. 3-4 times over the lifespan of the disc, equivalent to having an "as new" disc each time

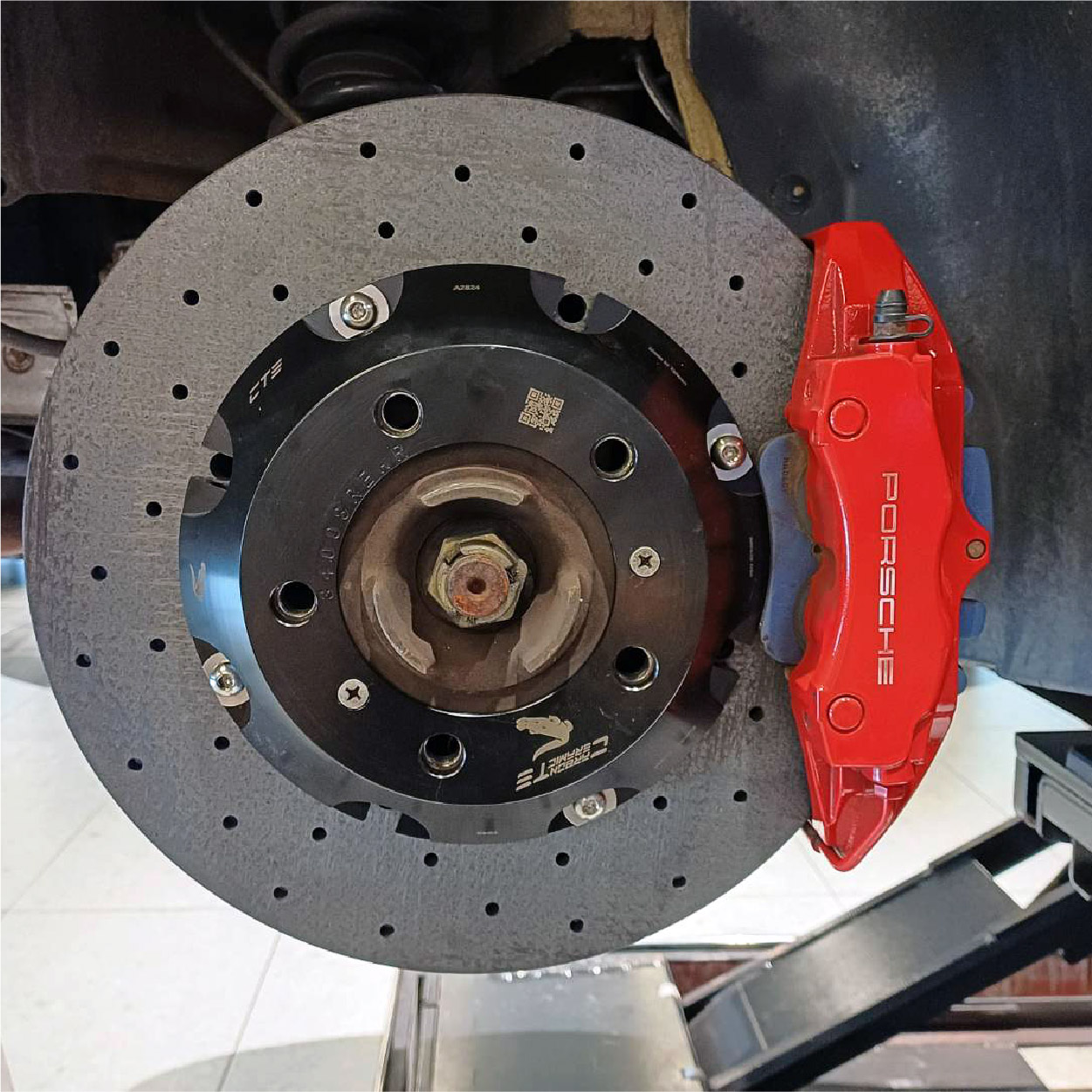

- Designed for use with OE Calipers, CTE Racing Calipers and select Aftermarket Calipers

- The ONLY brake manufacturer in the world to offer 290mm & 330mm fitments (for 15"/16"/17" wheels)

For Race Applications

- Can withstand much higher temperatures than iron discs & pads, thus reducing the chances of "Brake Fade" significantly

- Do not "warp" or "deform" at extreme track temperatures, thus do not experience uneven pad wear like iron discs & pads do

- Are far more durable than iron discs & pads, thus have a far longer service life

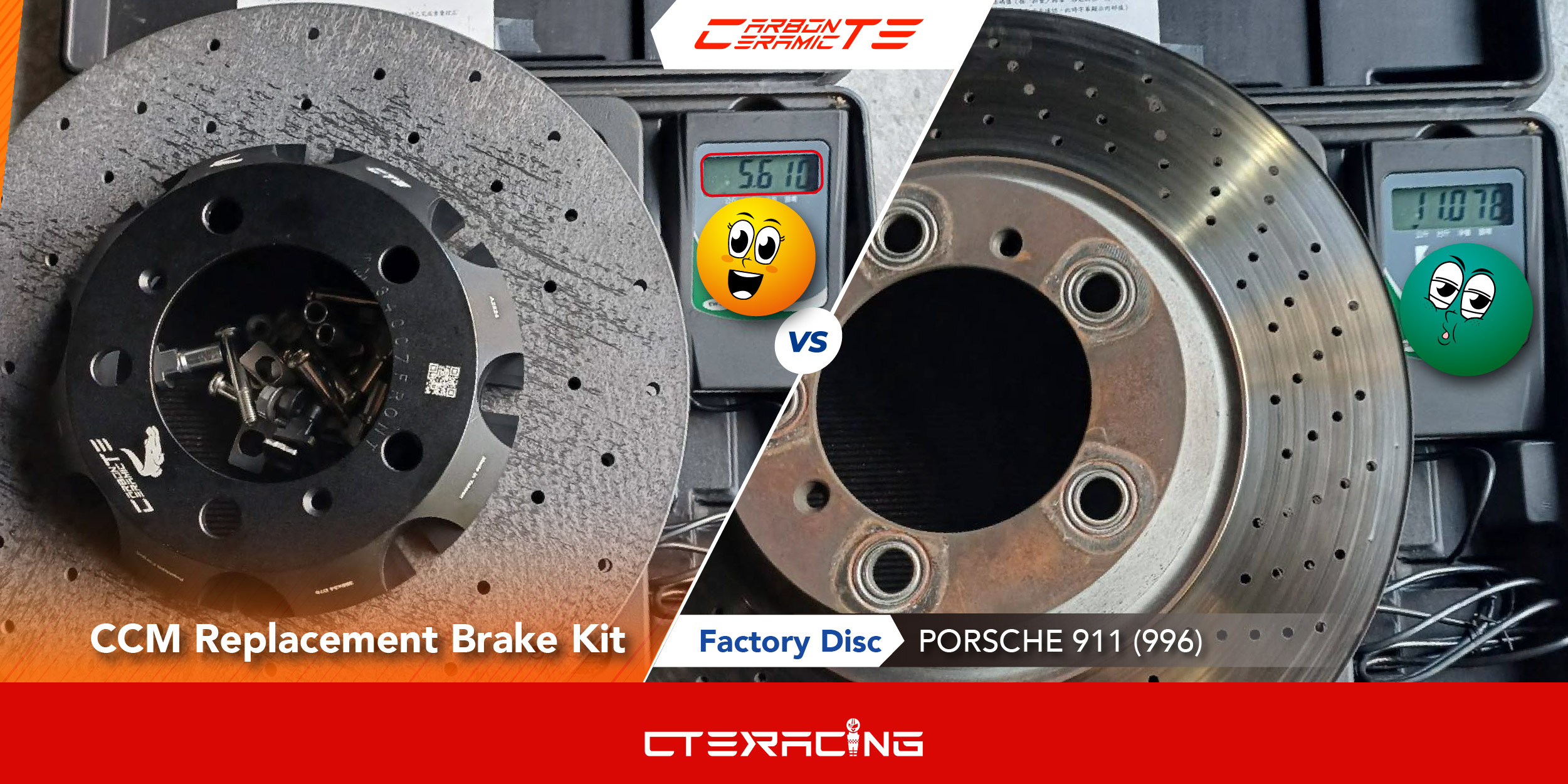

- Are, like-for-like, around 40-50% lighter than the equivalent iron disc, thus significantly reducing "rotating mass"

- Have a higher coefficient of friction than iron discs & pads, thus increasing braking performance

- Provide a more direct braking feel (you must use the correct pads)

- Improved braking performance in both wet & dry conditions, over the full operational temperature range (again, you must use the correct pads)

- Almost no brake dust whatsoever. Those who regularly wash their cars will most appreciate this

- Less noise, vibration and harshness (NVH. Again, you must use the correct pads)

- Have a service life over 3 times that of iron discs & pads. In other words, they will last you almost the lifetime of your car

- For the show car (yes, we realise some of you may find this cringe), nothing looks better than Carbon Discs that fill your wheels

- For those that already have Carbon Ceramic Brakes on their High-End performance car, superior direct-replacement brakes at 50% of the cost!

- Our Carbon Ceramic Brakes are listed by both Disc Size (Universal) and by Vehicle Fitment

- If you are ordering a Custom/Universal Disc and know the EXACT Disc Size that you require, please include your Vehicle Model and required PCD and Offset in your Order Notes as we require this to make your custom bell

- All CTE Carbon Ceramic Brakes use our Patented M8 Fastener Technology. If you are ordering the Disc Only (i.e Without Bell), our fasteners will be included alongside a Technical Diagram for the Disc

- Carbon Ceramic Brakes will only work effectively with large Racing Calipers due to the required friction surface area on the brake pads

- Typically, this covers all OEM/Aftermarket 6-Pot Calipers and some OEM/Aftermarket 4-Pot Calipers (with minimum 30mm OEM Disc Thickness)

- Carbon Ceramic Brakes can ONLY be used with CCB-Friendly (Carbon Ceramic) Brake Pads

- If you do not know which CCB-Friendly Brake Pads you can use with your Caliper, please Contact Us BEFORE ordering

- If the relevant CCB-Friendly Brake Pad (OEM or Aftermarket) is not available for your Caliper, there is a high chance you will be required to upgrade your Calipers as well. Please Contact Us and we will check availability

Due to the nature of For Race Use Only products, CTE Carbon Composites will provide a limited 1 year warranty for all Carbon Ceramic Brakes to be free of defects in materials and workmanship upon receipt of product and time of professional installation. It is the sole responsibility of the buyer/installer to verify the suitability for installation. Parts once used will not be covered under warranty. Parts returned must be determined by CTE Carbon Composites to be defective before any warranty credit or replacement is issued

CTE Carbon Composites's obligation under warranty shall be limited to repairing or replacing, at its option, any part proven defective. The customer must prepay transportation charges

Final determination of the suitability of the products for the use contemplated by the buyer is the sole responsibility of the buyer. CTE Carbon Composites shall not be liable for any special, direct, indirect, incidental, or consequential damages, that might be claimed as a result of the failure of any part, including claims for delay, loss of profits, or labor

CTE Carbon Composites shall not be liable for any damage or injury to persons or property resulting from improper installation or misuse of any part subject to this warranty

There are no other warranties expressed or implied extending beyond those set forth above

CTE Carbon Composites's obligation under warranty shall be limited to repairing or replacing, at its option, any part proven defective. The customer must prepay transportation charges

Final determination of the suitability of the products for the use contemplated by the buyer is the sole responsibility of the buyer. CTE Carbon Composites shall not be liable for any special, direct, indirect, incidental, or consequential damages, that might be claimed as a result of the failure of any part, including claims for delay, loss of profits, or labor

CTE Carbon Composites shall not be liable for any damage or injury to persons or property resulting from improper installation or misuse of any part subject to this warranty

There are no other warranties expressed or implied extending beyond those set forth above